Autobag® PS 125 and PS 125 OneStep™ Tabletop Baggers

- Hand load system operates at speeds up to 25 bags per minute (15 bpm OneStep version)

- Compact, tabletop design

- All-electric system (no air required)

- Locking turntable stand for fast and easy bag changeover

- Onboard job storage and system diagnostics

- Automatic or manual operating modes for optimum flexibility and productivity

- Next-bag-out printing prevents product queuing and bag waste

- Tilt-back printer head for easy maintenance

Autobag® AB 180™ High-speed Bagger

- Semi- to fully-automatic system operates at speeds up to 80 bags per minute

- Quick to set-up, easy to operate, reliable and fast

- Easily change bag sizes in less than two minutes

- Operator-friendly touch screen accesses job storage and onboard diagnostics

- Combine with Autobag thermal transfer imprinters for complete inline product identification and labeling

- Integrates with a range of Autobag and third-party infeed equipment

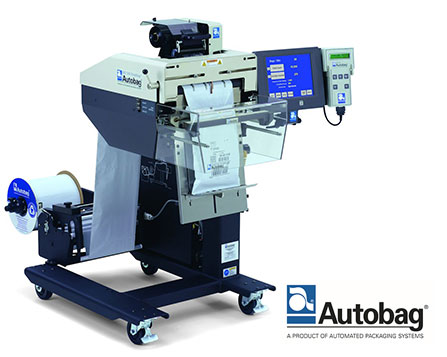

Autobag® AB 180 OneStep™ Bagger with Integrated Printer

- Semi-automatic system operates at speeds up to 30 bags per minute

- Next-bag-out printing is ideal for short production runs with frequent changeovers

- Integrates with warehouse management systems for mail order fulfillment packing and shipping

- Prints high-resolution text, graphics and bar codes directly on the bag, eliminating the need for a separate labeling operation

- Operator-friendly touch screen accesses job storage and onboard diagnostics

- Tilt-back printer head for easy maintenance

- Easily change bag sizes in less than 2 minutes

Autobag® AB 255™ Wide Bagger

- Semi- to fully-automatic system operates at speeds up to 55 bags per minute

- Runs bags up to 16 in. wide x 26 in. long

- Quick to set-up, easy to operate, reliable and fast

- Easily change bag sizes in less than 2 minutes

- Operator-friendly touch screen accesses job storage and onboard diagnostics

- Combine with Autobag thermal transfer imprinters for complete inline product identification and labeling

- Integrates with a range of Autobag and third-party infeed equipment

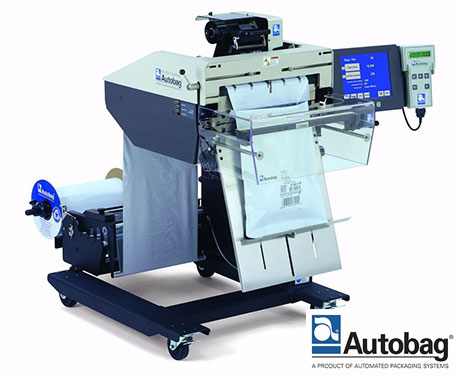

Autobag® AB 255 OneStep™ Wide Bagger with Integrated Printer

- Semi-automatic system operates at speeds up to 30 bags per minute

- Runs bags up to 16 in. wide x 27 in. long

- Next-bag-out printing is ideal for short production runs with frequent changeovers

- Integrates with warehouse management systems for mail order fulfillment packing and shipping

- Prints high-resolution text, graphics and bar codes directly on the bag, eliminating the need for a separate labeling operation

- Operator-friendly touch screen accesses job storage and onboard diagnostics

- Tilt-back printer head for easy maintenance

- Easily change bag sizes in less than two minutes

Autobag® 850S™ Mail Order Fulfillment Bagger

- Semi-automatic system runs bags up to 22 in. wide x 36 in. long

- State-of-the-art technology enables an extra wide bag opening, up to 11 in. x 11 in., minimizing bag size requirements for multi-line orders

- Next-bag-out printing ensures accuracy and eliminates the need for a separate labeling operation

- High-quality, wrinkle-free seals

- Intuitive touch screen interface accesses tutorials, help system, diagnostics, and onboard job storage; graphic-based controls make navigation simple

- Compact footprint minimizes floor space requirements

- Highly flexible system easily integrates with third-party infeeds, picking systems, etc.

AirPouch® Express 3 Void-fill System

- On-demand inflator system provides void-fill air pillows in semi-automatic or automatic modes

- Compact, benchtop system operates at speeds over 50 feet per minute

- Knifeless design eliminates primary wear item found on other void-fill machines

- Boxed material requires less lifting and fewer changeovers

- EZ-Tear™ perforations between each pillow for easy separation and less waste

- Pillows are available in EarthAware™ recycled and biodegradable blends

AirPouch® FastWrap™ Protective Packaging System

- On-demand inflator system provides cushioning wrap and block-and-brace tubes

- Compact system operates at speeds up to 65 feet per minute

- Intelligent design regulates heat, air and speed for consistent fill level and seal quality

- One small, high-yield box equates to 5.5 rolls of bundle bubble

- Bubbles come in a patented, channel-filled honeycomb design that prevents shipping damage, reducing product losses and returns

- Wrap and tubes are available in EarthAware™ recycled and biodegradable blends

SidePouch® FAS SPrint Revolution™ Food Grade Bagger

- Highly flexible system runs stand-up pouches and unsupported structures with no tooling changes

- Straightforward design and easy operator controls enable bag/pouch changeover in less than 5 minutes

- Hand-load with up to three operators, or communicate with up to two infeed devices at no additional cost

- Corrosion-resistant, stainless steel is ideal for harsh environments and daily washdown

- Small footprint, particularly for stand-up pouches

- Operates at speeds up to 900 inches per minute

- Advanced sealing system ensures consistent, high-quality seals

- System-matched SPrint SidePouch bags and pouches offer special features, such as reclosable zippers, resealable flaps, tamper-evident perforations, lamination, and more